A day's plan is in the morning, and a year's plan is in the spring. In this warm spring season, to ensure the safe and reliable operation of WHR power plant, all the existing BOOT project site team start to carry out the safety maintenance works.

WUHAI BOOT WHR Plant

With the shutting down of WUHAI cement production line, the equipped BOOT WHR power plant also enters the maintenance period.

All maintenance works are carried out in an orderly manner, firstly making a detailed maintenance plan, and then implementing it. The daily meeting is held on every morning to summarize the maintenance works of yesterday, deploy the maintenance tasks of today, strictly track the maintenance progress, and ensure the maintenance quality. Adhere to the policy of "Safety First, Prevention Prevail", and formulate strict and feasible safety measures. Hold regular safety meetings to impart safety knowledge and improve safety awareness. The responsibility shall be assigned to specific person to ensure the smooth completion of the maintenance works.

Safety Maintenance Mobilizing

Maintain Valves, Make up oil, Clean Water System, Rectify Boiler Dedusting System.

CHUZHOU BOOT WHR Plant

On Feb. 6th, the site team carried out urgent maintenance works for N0.2 AQC boiler conveyors. In the early morning 5:30 am, Plant Manager Mr. Song Yongjun got a telephone call from the on-duty shift manger Mr. Ben Peisong, being informed that red ashes entered boiler conveyor and the conveyor was forced to be manually shut down. Mr. Song immediately called Mr. Zhang Yuqin and Mr. Gengjiali, another two off-duty operators, to come to the site for emergency maintenance works.

Mr. Song Yongjun instruct Mr. Wang Bingliang (on-duty operator) to disconnect the conveyor power switch, hang up the sing board “Under working, No Connection”. Everybody was told to wear the PPE properly to prevent any potential damage. After being assigned specific works, all people moved to their positions starting the maintenance works. Being exposed to the high temperature ashes, all people worked together. After two hours emergency maintenance, the conveyor achieved the startup.

SHIJIAZHUANG BOOT WHR Plant

On March 2, the site team carried out the physical-electromagnetic-scale-inhibition transformation on the circulating water system. Under the conditions that the time was tight, the task was heavy, and the manufacturer's technicians did not arrive at the site, the plant manager Mr. Wang Weide resolutely decided to rely on the staff to carry out the work. Led by Mr. Zhang Wenhong, the maintenance team leader of WHR olant, Cui Wei, Zhang Lei, Feng Yonggang, Yang Weimin and Zhang Yajun were divided into two teams, and the pipelines of three water pumps were reconstructed at the same time. Without the guidance of professional personnel, based on many years of work experience, self-measured data, they overcame adverse factors such as insufficient technical parameters, gave full play to the subjective initiative of all inspection personnel, and went all out to carry out the works. Until the lunch time, everyone was still working selflessly.

Through the joint efforts of all staff, the preliminary work of physical-electromagnetic-scale-inhibition transformation was successfully completed, which won valuable time for water injection of circulating water tank in the later stage. The employees have always been maintaining the hard work and dedication virtue, and make sustained efforts to contribute to the faster, more efficient and more energy-saving development of the company.

SHOUGUANG BOOT WHR Plant

After the Spring Festival, the site team timely carried out the maintenance works for the important rotating equipment. On the precondition that all equipment has been shut down, the maintenance staff started the comprehensive inspection works with wearing proper PPEs. Check the coupling, protective cover and anchor bolt are loose or not, the grounding wire is good or not, and supplement necessary lubricating oil for rotating equipment…

The periodic maintenance of equipment is the drive power for the safe production and long-term operation. The site team will continue doing the periodic maintenance works, paying attention to the operation status of main equipment, combining the maintenance and patrol inspection together, finally achieving the safety production purpose.

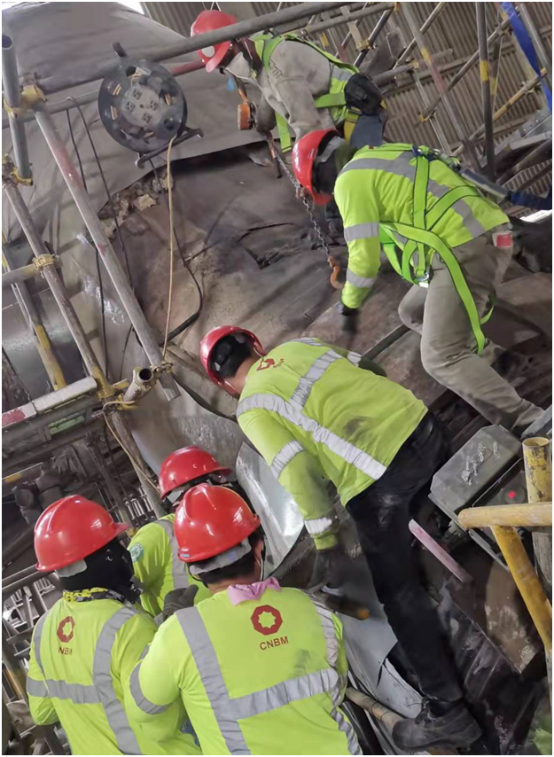

Philippines SOLID BOOT WHR Project

In January, due to the failure of the grate cooler, the cement plant stopped the production. During the shutdown period, the WHR site team seizing the limited time immediately organized the staff to do the gas duct repairing works. From the safety analysis and work permit applying to the safety work arrangement such as supervisor appointing, maintenance scheme finalizing and PPE preparing, all works are strictly following the requirements of Operation Specifications and ensure safety always comes the first.

Due to the passionate and high-spirited working atmosphere of all maintenance staff, the repair works smoothly completed. The average inlet temperature for AQC boiler increased by 10 ℃, and the power generation accordingly increased about 10kW.