China Government and CNBM Group Attitude Towards CO2 Emission Reduction

Sep. 22nd,2020, President Mr. Xi Jinping made commitment on the UNGA that China will take more powerful measures to achieve the Carbon Emission Peak by 2030 and realize the Carbon Neutral target by 2060.

In the 1st meeting after China New Year, CNBM Secretary of CPC Committee and Chairman Mr. Zhou Yuxian stressed that to achieve “Peak Carbon Dioxide Emissions” and “Carbon Neutrality” is a significant decision and deployment from CPC Central Committee. CNBM, as the only one central government-owned enterprise in the building material fields, will take this work as one of the most important contents in the group’s “14th Five-Year-Plan”.

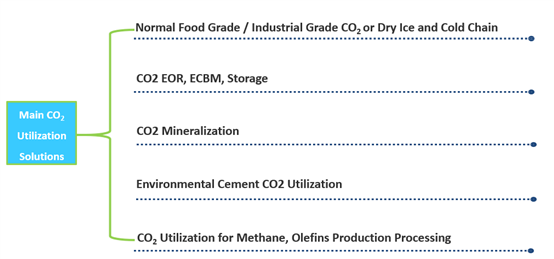

Main CO2 Utilization Solutions

CO2 Capturing In Cement Plant

Preheater gas firstly goes through PH boiler for heat exchanging, then goes to raw mill for drying, then come to the BF for de-dusting. At the outlet of BF the gas temperature will drop to 40-60 Deg. C and then will be guided via ID fan to the CO2 absorber tower.

In the absorber tower the CO2 will be absorbed by MEA, the clean gas will exhaust from the top of absorb tower into atmosphere. The rich MEA after absorbing CO2 will be pumped to the heat exchanger for temperature raising (up to 110 Deg. C), then come to the de-sober to separate the CO2. The separated CO2 will be guided to the precision processing procedures. After compressing, de-humidification, de-sulfuration, refrigeration etc. steps finally we could get the liquid CO2.

Advantages of CO2 Capturing In Cement Plant

Cement industry is one big CO2 emission source among the various industries. There are two direct CO2 emission points from the cement production process: one is the Carbonate decomposition caused CO2 emission, the biggest source in the cement process, accounting for 55% of total emission; the other one is fossil fuel burning caused CO2 emission, accounting for 32% of the total emission. Besides the direct emission sources, the power consumption during cement production process also indirectly contribute 13% CO2 emission. According to the calculations, per ton clinker production will cause 0.935t CO2 emission. In the preheater gases, the CO2 account for 20-30%.

Due to cement waste gas composition is simple (no SO2 contained), there is no de-sulfurization equipment.

The heat utilized in the CO2 capturing process could be provided by the waste heat recovery boiler, in this way the total cost could be further reduced.

Sinoma Development in CCUS

Sinoma and CCS Knowledge Center (Canada) signed a design consulting contract for Heidelberg Lehigh Cement Plant in Canada in 2020. Now the contract is proceeded smoothly.

This project execution symbolized that Sinoma had made a firm step in CCUS field and will lay a solid foundation for the further industrialization of CCUS. Sinoma will be continuously dedicated into this career。